Automated Stamping Machine

Goal:

Using a single motor, create an automated machine to receive, stamp and eject medallions.

Process:

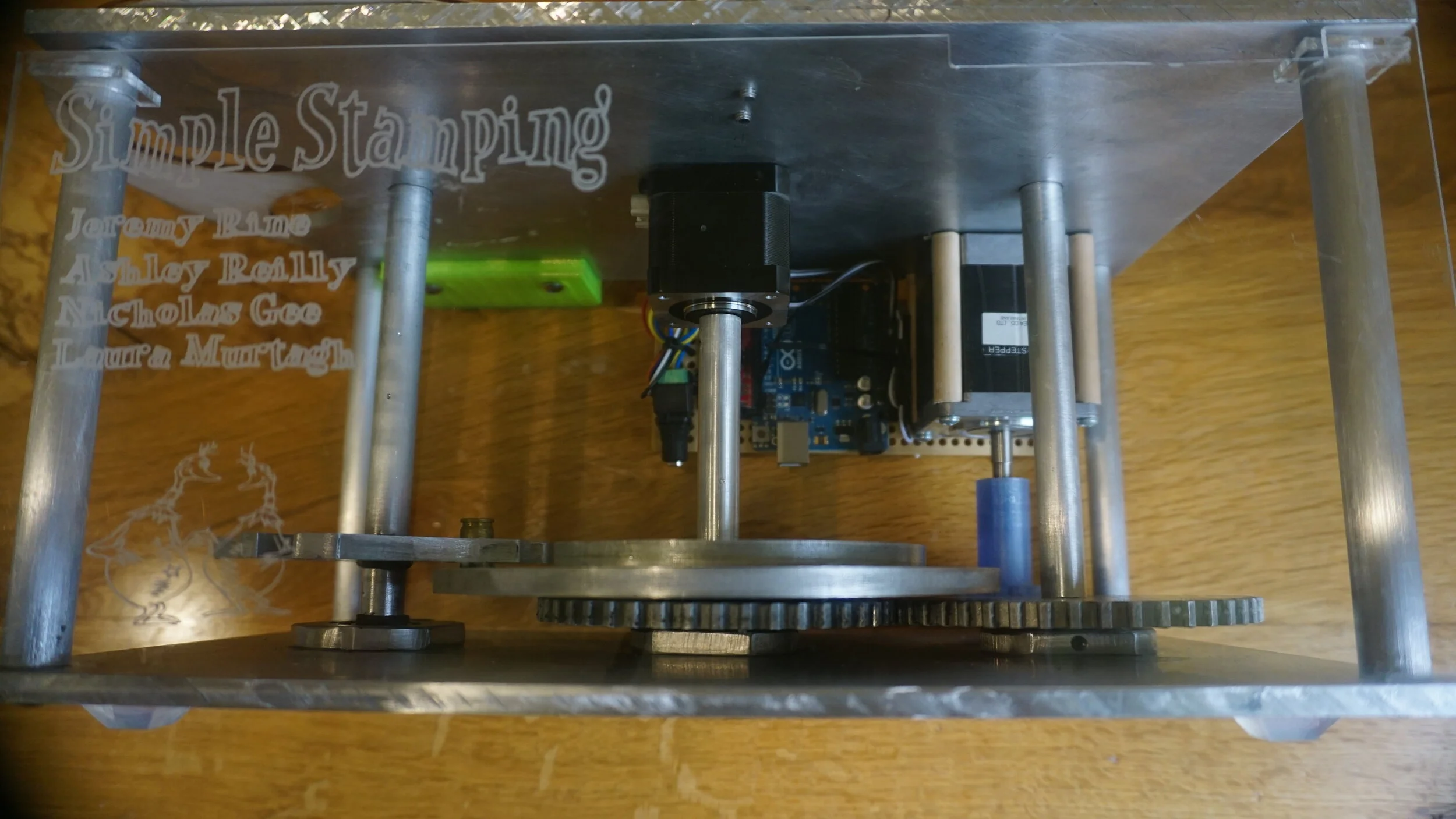

To eliminate the need for computer controls a four position Geneva Wheel was selected to translate a constant velocity input into a timed output. A prototype made from laser cut plywood was used to verify the concept and dimensions.

Innovation:

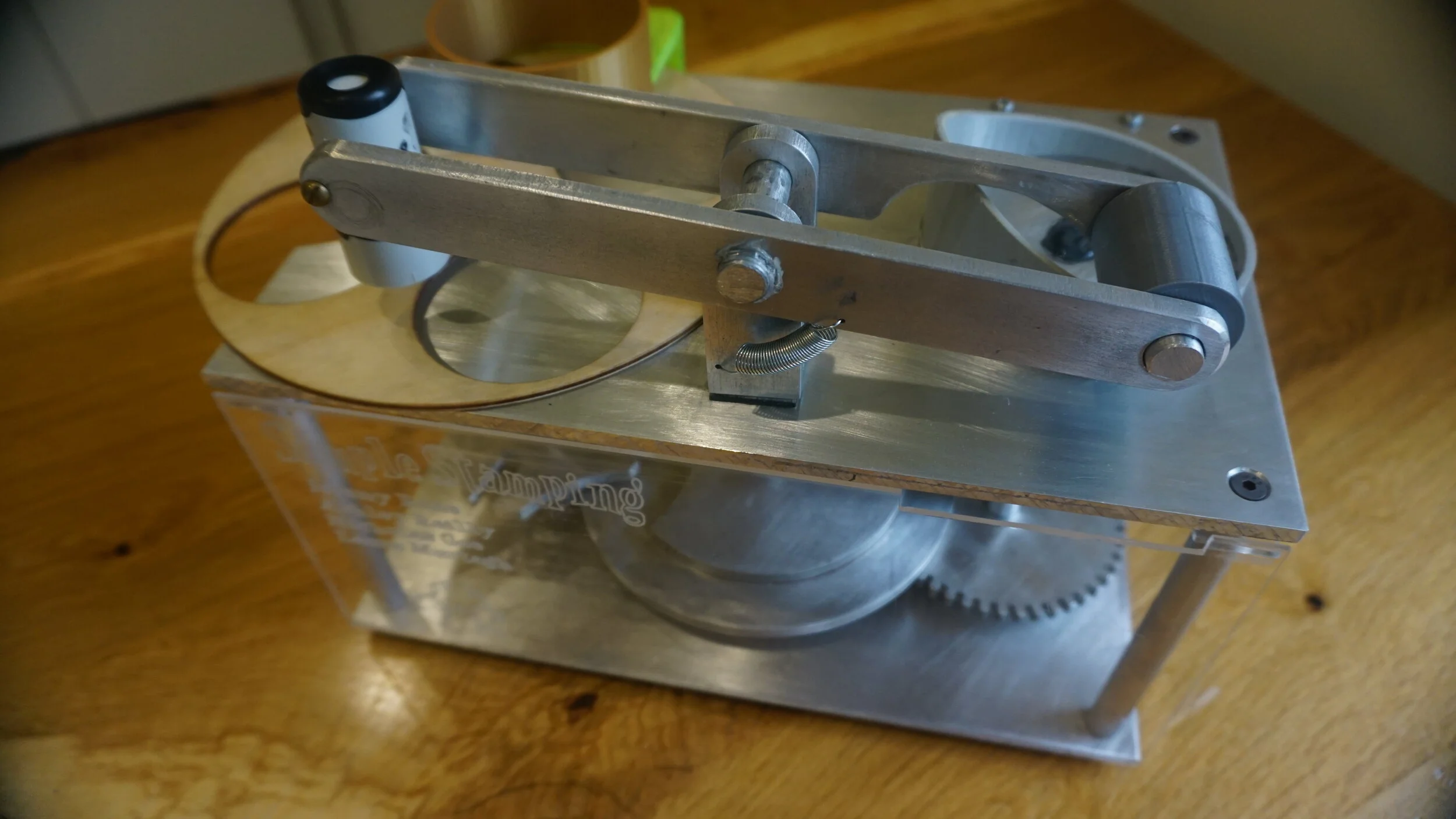

To add further mechanically controlled timing to the machine, a cylinder cam “circam” was developed which gave designed motion of a swing arm through each complete rotation. Only a single motion was needed for this application but a complex behavior could easily be adapted to this design.

Challenges:

The final unit was built from aluminum to give a robust structure. The prototypes were built from wood which were easily glued together, thus design changes had to be made to accommodate a hardware based attachment systems.

Lessons Learned

More time should have been spent on motor torque requirements. In the final days of the project a new motor had to be added in a new location with corresponding gear to get enough torque to run the machine. The original motor was left in place but not powered for alignment purposes (keeping this a one motor machine). Using direct drive from the motor limited our ability to adjust torque for this prototype.