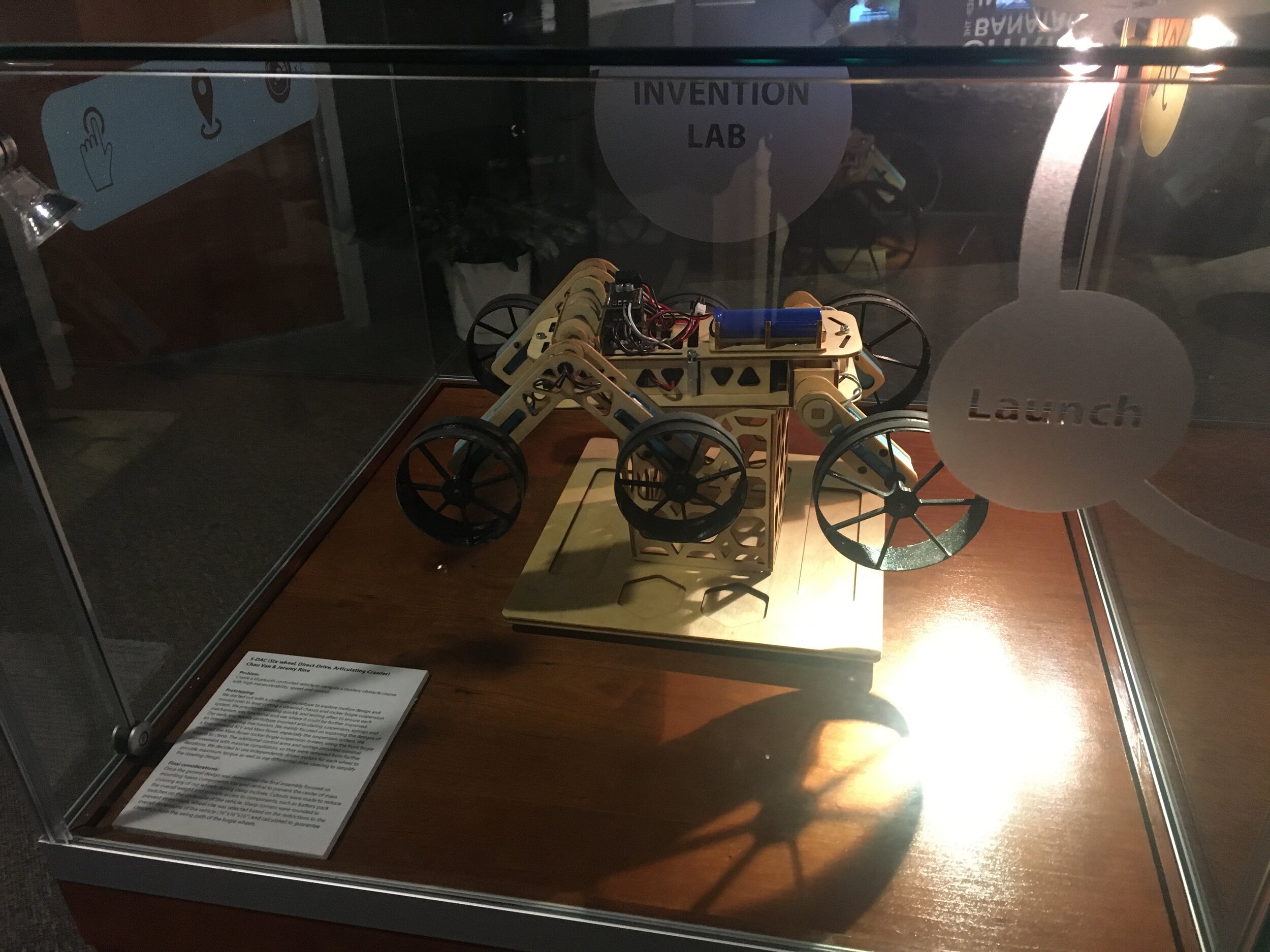

S-DAC

Goal:

Build a blue-tooth controlled vehicle to drive through an obstacle course of unknown design.

Process:

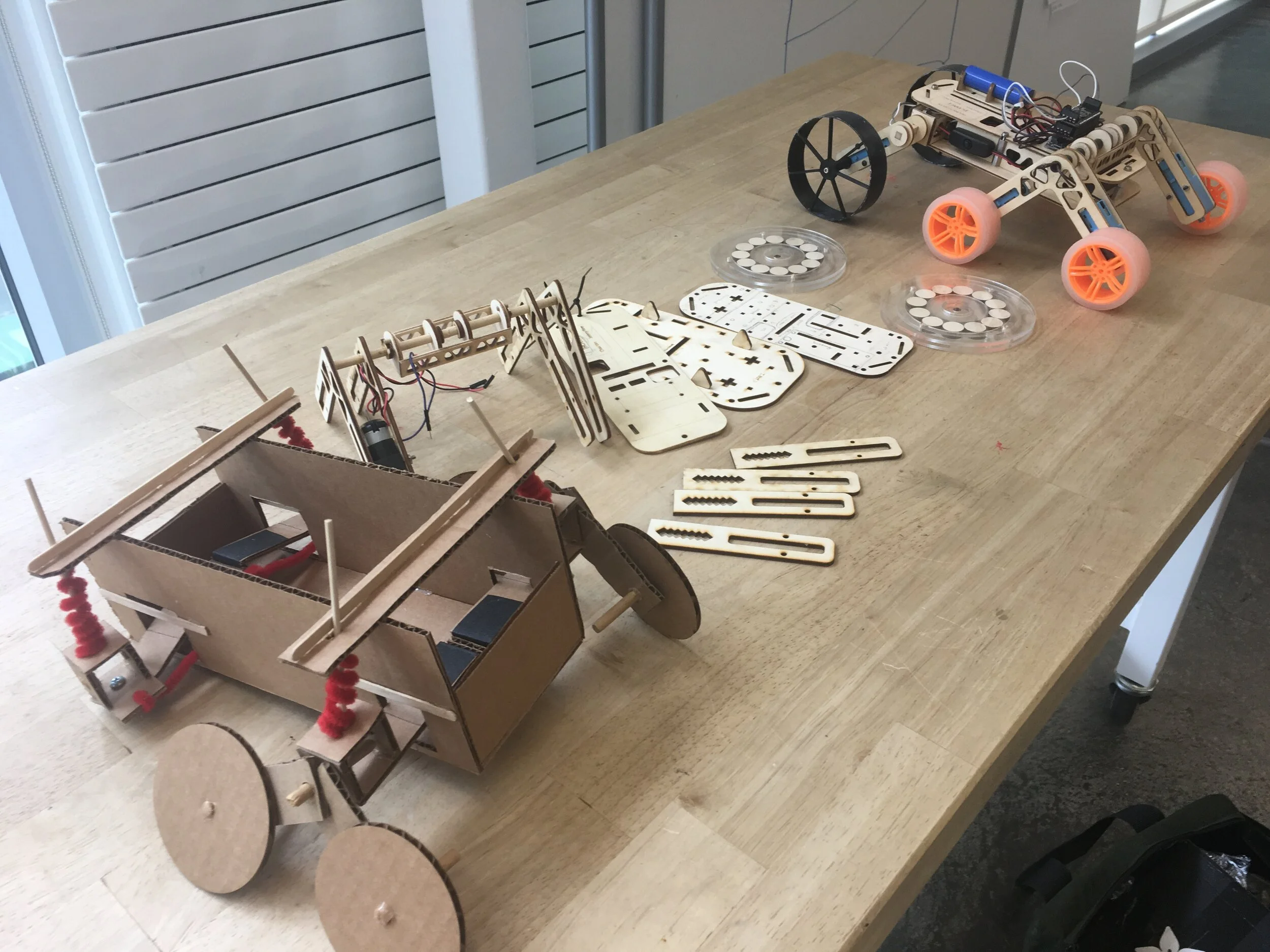

Starting with a cardboard mock-up the general size and mechanisms were determined.

Using laser cut plywood, initial components were designed with adjustable lengths and mounting options. These pieces allowed real world testing with the ability to make quick changes without having to make new parts.

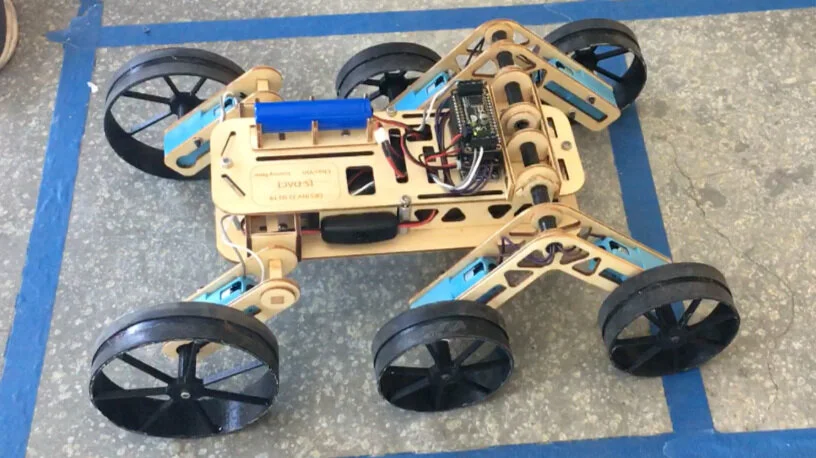

The final build components were built having learned from the function of the test pieces. Cutouts were made for weight reduction, and corners radused to eliminate stress risers and overall aesthetics.

Challenges:

The electronic components to use a bluetooth controller (iPhone) and drive the motors was a new area of knowledge. Using school and online resources to quickly learn how to write code for the control system was critical to the success of the project.

Applying engineering kinematics to the code allowed for the vehicle to drive smoothly with different size wheels and prevent tire scrubbing while turning.

Lessons Learned

From this project extensive skill improvements were made in rapid prototyping with a laser-cutter, 3D printing, and programming using Arduino IDE.